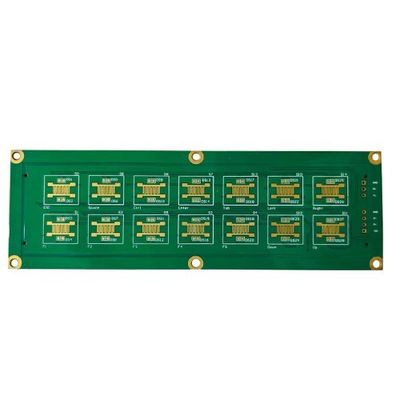

Green Prototype PCB Assembly 2-Layer PCB With Min Solder Mask Bridge Of 0.1mm

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Test Method | Flying Probe Test | Min Line Width/Space | 0.1mm/0.1mm |

|---|---|---|---|

| Min Solder Mask Bridge | 0.1mm | Min Hole Size | 0.2mm |

| PCB Size | 100mm*100mm | Solder Mask Color | Green |

| Min Annular Ring | 0.1mm | PCB Material | FR4 |

| Highlight | Green Prototype PCB Assembly,FR4 2-Layer PCB,2-Layer Prototype PCB Assembly |

||

Product Description:

Prototype PCB Assembly is a type of PCB (Printed Circuit Board) that is used for creating prototypes of electronic circuits. It is an essential component in the process of product development and testing for various industries such as electronics, automotive, aerospace, and medical equipment.

Prototype PCB Assembly is made of FR4 material, which is a type of flame-retardant glass-reinforced epoxy laminate. This material is widely used in the production of PCBs due to its excellent electrical insulation, mechanical strength, and dimensional stability.

The PCB size for Prototype PCB Assembly is 100mm*100mm, making it suitable for small and medium-sized electronic projects. The minimum hole size for this product is 0.2mm, which allows for precise and accurate placement of components.

The product name, Prototype PCB Assembly, reflects its purpose of being a quick and cost-effective solution for creating prototypes of electronic circuits. It is also known as prototyping PCB or prototype circuit board.

Prototype PCB Assembly is a 2-layer PCB, meaning it has two layers of conductive material separated by an insulating layer. This design is suitable for simple electronic circuits and helps to reduce the overall cost of the product.

The process of Prototype PCB Assembly fabrication involves several steps, such as designing, printing, etching, soldering, and testing. The first step is to design the PCB layout using computer-aided design (CAD) software. This layout is then printed onto the FR4 material using a specialized printer.

Next, the conductive layers are etched onto the PCB using a chemical process, leaving behind the desired circuit traces. The holes for components are drilled, and then the PCB is coated with a thin layer of solder mask to protect it from corrosion.

Once the PCB fabrication process is complete, the next step is to assemble the components onto the board. This process is known as PCB Assembly Manufacturing, and it involves placing electronic components onto the PCB and soldering them in place.

The components used in Prototype PCB Assembly are usually surface-mounted devices (SMDs), which are smaller and more compact than through-hole components. This allows for a higher density of components on the PCB and reduces the overall size of the product.

The PCB Assembly Manufacturing process starts with the preparation of components, where they are sorted, counted, and checked for any defects. The assembly process starts with solder paste being applied to the PCB, followed by the placement of components using automated equipment.

Once all the components are in place, the PCB is heated, causing the solder paste to melt and create a bond between the components and the board. After cooling, the PCB is inspected for any defects, and any necessary rework is done to ensure the quality of the product.

Quality control is an essential aspect of PCB Assembly manufacturing. The PCB is inspected at various stages of the process to ensure that it meets the required standards and specifications. This includes checking for correct component placement, proper soldering, and functionality testing.

The final step in quality control is the testing of the assembled PCB. This involves applying power to the circuit and checking for any failures or malfunctions. Any issues found during testing are addressed, and the PCB is retested until it meets the required standards.

PCB Assembly testing is a crucial step in the production process as it ensures the functionality and reliability of the product. There are various testing methods used, such as in-circuit testing, functional testing, and flying probe testing, to name a few.

In-circuit testing involves checking the electrical connections and functionality of each component on the PCB. Functional testing, on the other hand, checks the overall performance of the circuit. Flying probe testing uses a specialized machine to test for electrical continuity and any potential defects on the PCB.

Prototype PCB Assembly is an essential product in the electronics industry, playing a vital role in the development and testing of new electronic products. Its high-quality fabrication, efficient assembly process, and rigorous quality control measures make it a reliable and cost-effective solution for creating prototypes of electronic circuits.

Features:

- Product Name: Prototype PCB Assembly

- Min Line Width/Space: 0.1mm/0.1mm

- Min Annular Ring: 0.1mm

- PCB Size: 100mm*100mm

- Min Hole Size: 0.2mm

- PCB Thickness: 1.6mm

- PCB Prototype Fabrication

- High Quality PCB Prototype Assembly

- Fast Turnaround Time

Technical Parameters:

| Product Name | Prototype PCB Assembly |

|---|---|

| Printed Circuit Assembly | Single-sided/Double-sided/Multi-layer |

| Printed Board Assembly | Single-sided/Double-sided/Multi-layer |

| PCB Assembly Manufacturing | Quick Turn/High Volume |

| PCB Size | 100mm*100mm |

| PCB Thickness | 1.6mm |

| Copper Weight | 1oz |

| PCB Material | FR4 |

| Surface Finish | HASL |

| Min Solder Mask Bridge | 0.1mm |

| Solder Mask Color | Green |

| Silkscreen Color | White |

| Test Method | Flying Probe Test |

Applications:

Welcome to JIETENG, your one-stop destination for high-quality Printed Circuit Assembly (PCA) services. As a leading manufacturer and supplier of PCBs, we are committed to providing you with top-notch products that meet your specific requirements and exceed your expectations.

Our PCB circuit board is a 2-layer board made in China with a copper weight of 1oz. It has a minimum annular ring of 0.1mm, making it perfect for high-density applications. With a surface finish of HASL and a white silkscreen color, this board is not only visually appealing but also offers excellent durability and reliability.

Our Prototype PCB Assembly is suitable for a wide range of applications, including but not limited to:

- Consumer electronics

- Industrial equipment

- Medical devices

- Automotive electronics

- Telecommunications

Whether you need a custom PCB for a small project or a large-scale production, our PCB assembly service has got you covered. We have the expertise and resources to handle projects of any size and complexity.

Choosing JIETENG for your Printed Board Assembly needs comes with numerous benefits, including:

- High-quality products at competitive prices

- Quick turnaround time

- Stringent quality control processes

- State-of-the-art equipment and technology

- Experienced and skilled team

- Flexible and personalized solutions

Our goal is to provide you with a hassle-free experience and deliver products that meet your exact specifications. We understand the importance of time and cost in today's fast-paced business world, and we strive to offer efficient and cost-effective solutions to our clients.

At JIETENG, we are dedicated to delivering high-quality, reliable, and cost-effective Printed Circuit Assembly services. Our commitment to customer satisfaction and continuous improvement has made us a preferred choice for many clients worldwide.

Trust us for all your PCB Assembly needs and experience the difference in quality and service. Contact us today to learn more about our PCB circuit board and other products and services. We look forward to working with you and helping you bring your ideas to life!

Customization:

Brand Name: JIETENG

Model Number: PCB circuit board

Place of Origin: China

Min Hole Size: 0.2mm

Min Solder Mask Bridge: 0.1mm

Product Name: Prototype PCB Assembly

Silkscreen Color: White

PCB Material: FR4

PCB Assembly Manufacturing - JIETENG offers high-quality PCB Assembly Manufacturing services for your custom needs. Our Printed Board Assembly process includes PCB Prototype, PCB Fabrication, PCB Manufacturing, and Printed Circuit Board Assembly. Trust JIETENG for all your Printed Board Assembly needs.

Packing and Shipping:

Our Prototype PCB Assemblies are carefully packaged to ensure safe and secure delivery to our customers. Each assembly is packaged according to its size and delicacy, with extra precautions taken for fragile components.

The assembly is first placed in an anti-static bag to protect the electronics from any potential damage caused by static electricity. It is then placed in a sturdy cardboard box with ample padding to prevent movement during transit.

For additional protection, bubble wrap or foam may be used to further secure the assembly. In some cases, a custom-made foam insert may be used to fit the specific dimensions of the assembly.

Once the assembly is packaged, it is labeled with the necessary shipping information, including the recipient's name and address, and a tracking number is provided for easy tracking of the package.

We offer various shipping options to accommodate our customers' needs, including standard and expedited shipping. Our team works closely with trusted shipping carriers to ensure timely and efficient delivery of our assemblies.

At Prototype PCB Assembly, we take great pride in our packaging and shipping processes to ensure that our customers receive their assemblies in pristine condition. Contact us today to learn more about our services and how we can assist with your PCB assembly needs.

FAQ:

- Q: What is the brand name of this product?

A: The brand name of this product is JIETENG. - Q: What is the model number of this product?

A: The model number of this product is PCB circuit board. - Q: Where is this product manufactured?

A: This product is manufactured in China. - Q: What materials are used to make this product?

A: This product is made from high-quality PCB materials. - Q: Does this product come with a warranty?

A: Yes, this product comes with a warranty against manufacturing defects.