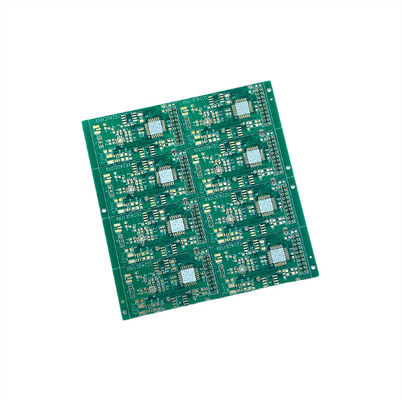

8 Layer PCB SMT Assembly Printed Circuit Board Blind Buried Via Board

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Silk Screen Color | White | Components Pitch | 0.5mm |

|---|---|---|---|

| Product Type | PCB SMT Assembly | Min. Line Width/Space | 0.1mm/0.1mm |

| Copper Thickness | 1oz | Surface Finish | HASL |

| PCB Size | 100mm*100mm | PCB Thickness | 1.6mm |

| Highlight | 8Layer PCB SMT Assembly,100x100mm PCB SMT Assembly,8Layer Printed Circuit Board |

||

8-Layer Board PCB +SMT Assembly Printed Circuit Board Blind Buried Via Board

Product Description:

PCB SMT Assembly is a complex process that requires expertise and precision in order to ensure accuracy and reliability for the electronic device. It involves the soldering of components onto a printed circuit board (PCB) using surface-mount technology (SMT). Our PCB SMT Assembly is designed to meet the highest quality and safety standards with a 2-layer PCB, 1.6mm thickness, 1oz copper thickness, and a minimum hole size of 0.2mm. We specialize in printed circuit board soldering and electronic circuit board assembly, ensuring the finest workmanship with each product. Our PCB SMT Assembly is a precise and reliable solution for any electronic device.

Features:

- Product Name: PCB SMT Assembly

- Min. Line Width/Space: 0.1mm/0.1mm

- Copper Thickness: 1oz

- Solder Mask Color: Green

- Test Type: Flying Probe Test

- Product Type: PCB SMT Assembly

- Features: Electronic Circuit Board Assembly, Printed Circuit Board Soldering, Printed Circuit Board Soldering

Technical Parameters:

| Features | Parameters |

|---|---|

| PCB Size | 100mm*100mm |

| Copper Thickness | 1oz |

| Components Pitch | 0.5mm |

| PCB Layer | 2-Layer |

| Product Type | PCB SMT Assembly |

| PCB Thickness | 1.6mm |

| Min. Line Width/Space | 0.1mm/0.1mm |

| PCB Material | FR-4 |

| Solder Mask Color | Green |

| Min. Hole Size | 0.2mm |

Applications:

JIETENG PCB SMT Assembly is the perfect choice for Printed Circuit Board Soldering Assembly. It is manufactured with Brand Name JIETENG, high quality Model Number PCB circuit board, Place of Origin China, Silk Screen Color White, and Solder Mask Color Green. It also features PCB Material FR-4, PCB Size 100mm*100mm, and Components Pitch 0.5mm, making it the ideal solution for Surface Mount Soldering Assembly.

JIETENG PCB SMT Assembly is designed to provide reliable and efficient Printed Circuit Board Soldering Assembly. It is highly robust and durable, which makes it perfect for long-term use. The product is easy to use and install, and requires minimal maintenance. Moreover, it has a low cost of ownership, which makes it a great value for money.

With its high-quality components, JIETENG PCB SMT Assembly is the ideal solution for all your Printed Circuit Board Soldering needs. It is designed to provide an efficient and reliable Printed Circuit Board Soldering Assembly that will last for years. Get your hands on this amazing product now and enjoy its great benefits!

Customization:

JIETENG PCB SMT Assembly

Brand Name: JIETENG

Model Number: PCB circuit board

Place of Origin: China

Test Type: Flying Probe Test

Components Pitch: 0.5mm

Product Type: PCB SMT Assembly

PCB Size: 100mm*100mm

Copper Thickness: 1oz

Our JIETENG PCB SMT Assembly is designed with high quality and precision for the best performance. It is equipped with a flying probe test that has a 0.5mm components pitch for superior accuracy. The PCB size is 100mm*100mm and the copper thickness is 1oz. Our PCB SMT Assembly is perfect for surface mount device assembly and electronic circuit board assembly.

Support and Services:

We provide comprehensive technical support and service for PCB SMT Assembly products. Our team of highly experienced engineers and technicians can assist you with every stage of the PCB SMT Assembly process, from design to fabrication, assembly and testing.

We offer a wide range of services, including:

- Design and engineering services

- Prototyping and fabrication

- Assembly and testing

- Troubleshooting and repair

We also provide ongoing technical support and training to ensure that your PCB SMT Assembly process is optimized for maximum efficiency and reliability.

If you have any questions or need assistance, please contact us at [email address] or call us at [phone number]. We look forward to helping you with your PCB SMT Assembly needs.

Packing and Shipping:

PCB SMT Assembly Packaging and Shipping:

Packaging: The PCB SMT Assembly products are individually packed with foam and placed inside a static-shielding plastic bag. The bag is then placed inside an anti-static box for extra protection.

Shipping: The PCB SMT Assembly products are shipped by standard air or ground transportation services. All packages are shipped with full insurance to ensure safe delivery.

FAQ:

- Q:What is PCB SMT Assembly?

- A:PCB SMT Assembly is a process of mounting surface-mount devices (SMDs) to a printed circuit board (PCB) made by JIETENG, with model number PCB circuit board, and origin from China.

- Q:What is the benefit of using PCB SMT Assembly?

- A:Using PCB SMT Assembly can help to save space and reduce the cost of production, while providing long-term reliability and increasing the density of components.

- Q:What materials are typically used in PCB SMT Assembly?

- A:The materials used in PCB SMT Assembly include printed circuit boards, surface-mount devices, solder paste, flux, and solder wire.

- Q:How long does it take to complete a PCB SMT Assembly?

- A:It usually takes about 4-6 hours to complete a PCB SMT Assembly, depending on the complexity of the design.

- Q:What type of equipment is used for PCB SMT Assembly?

- A:PCB SMT Assembly requires the use of pick-and-place machines, soldering machines, reflow ovens, X-ray machines, and other specialized equipment.