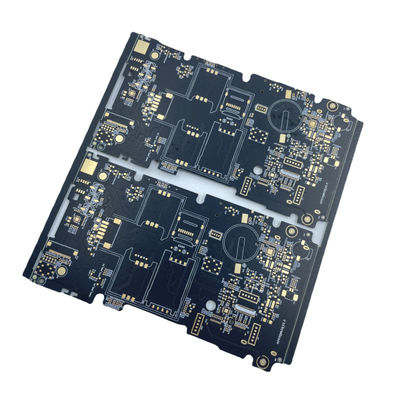

100mm*100mm Smt Circuit Board Assembly Green Solder Mask White Silk Screen

| Place of Origin | China |

|---|---|

| Brand Name | JIETENG |

| Certification | ISO/TS16949/RoHS/TS16949 |

| Model Number | PCB circuit board |

| Minimum Order Quantity | Negotiable |

| Price | Negotiable |

| Packaging Details | Blank carton, vacuum packed |

| Delivery Time | 5-8 working day |

| Payment Terms | Negotiable |

| Supply Ability | 360000 square meters / year |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Silk Screen Color | White | Test Type | Flying Probe Test |

|---|---|---|---|

| PCB Thickness | 1.6mm | Surface Finish | HASL |

| Min. Hole Size | 0.2mm | Components Pitch | 0.5mm |

| Min. Line Width/Space | 0.1mm/0.1mm | Product Type | PCB SMT Assembly |

| Highlight | 100mm*100mm smt circuit board assembly,green solder mask smt circuit board assembly,white silk screen smt printed circuit board |

||

Product Description:

PCB SMT Assembly is a type of Printed Wiring Board (PWB) assembly that involves the surface mount soldering of components onto the PCB. The process of assembling PCBs involves mounting and soldering components, such as ICs, resistors, and capacitors onto the board. The PCB is then tested to ensure the integrity of the PCB and the correct operation of the components. The PCB is then covered with a white silk screen layer to protect the components and provide a professional appearance. The PCB is then tested using a flying probe test to detect any potential problems. The PCB must have a minimum hole size of 0.2mm and a copper thickness of 1oz to ensure proper operation of the board. As an experienced PCB assembly manufacturer, we are committed to providing high-quality PCBs with excellent electrical performance and reliability for a wide range of electronic products. Our advanced manufacturing capabilities, combined with our commitment to quality, ensure that our PCBs exceed the highest industry standards and provide our customers with superior products. PCB SMT Assembly is the perfect solution for any project requiring a reliable, high-performance PCB.

Features:

- Product Name: PCB SMT Assembly

- Surface Finish: HASL

- Copper Thickness: 1oz

- Components Pitch: 0.5mm

- PCB Thickness: 1.6mm

- PCB Material: FR-4

- Surface Mount Soldering Assembly

- Electronic Circuit Board Assembly

- PCB Printed Wiring Assembly

Technical Parameters:

| Parameter | Value |

|---|---|

| Test Type | Flying Probe Test |

| Components Pitch | 0.5mm |

| Min. Hole Size | 0.2mm |

| PCB Thickness | 1.6mm |

| PCB Layer | 2-Layer |

| Product Type | PCB SMT Assembly |

| PCB Material | FR-4 |

| Surface Finish | HASL |

| Copper Thickness | 1oz |

| Solder Mask Color | Green |

Applications:

JIETENG PCB circuit board is a reliable and efficient electronic circuit board assembly solution. It is widely used in the industries of medical, automotive, aerospace, defense, etc. It is made of high quality FR-4 material with 1oz copper thickness, and the surface finish is HASL. The PCB size is 100mm*100mm. It is specially designed for a flying probe test.

JIETENG PCB circuit board's SMT assembly process is backed by the professional engineering team with many years of experience. The surface mount soldering assembly and printed circuit board soldering assembly are done with the highest accuracy and precision.

The advanced technology of JIETENG PCB circuit board assembly assists customers to reduce the cost and improve the product quality. It is a perfect choice for the industries mentioned above.

Customization:

JIETENG offers high-performance PCB SMT Assembly services with various parameters customizable to fit your needs. Our services feature the following:

- Brand Name: JIETENG

- Model Number: PCB circuit board

- Place of Origin: China

- Product Type: PCB SMT Assembly

- Solder Mask Color: Green

- PCB Layer: 2-Layer

- Min. Line Width/Space: 0.1mm/0.1mm

- Min. Hole Size: 0.2mm

We specialize in electronic circuit board assembly, surface mount device assembly, and PCB printed wiring assembly, so you can trust that your PCB SMT Assembly needs will be met with professionalism and quality.

Support and Services:

PCB SMT Assembly technical support and service includes:

- Providing answers to technical questions on PCB SMT Assembly.

- Assisting with troubleshooting for any technical issues.

- Providing advice for any desired modifications to PCB SMT Assembly.

- Providing solutions to ensure optimal performance of PCB SMT Assembly.

- Offering technical training and support to ensure proper use of PCB SMT Assembly.

- Assisting with installation, configuration, and maintenance of PCB SMT Assembly.

Packing and Shipping:

PCB SMT Assembly will be packaged and shipped in accordance with the following procedure:

- Before packaging, PCB SMT Assembly boards are inspected to ensure that they meet quality standards and are in good condition.

- Each PCB SMT Assembly board is then carefully wrapped in static-free material to protect it during shipping.

- The PCB SMT Assembly boards are then placed in a box with foam padding to protect them from shock and vibration during transit.

- The box is then sealed and labeled with the appropriate shipping information.

- The box is then shipped using a reliable shipping carrier.

FAQ:

- Q: What is PCB SMT Assembly?

- A: PCB SMT Assembly is a process of using surface-mounted components on a printed circuit board (PCB) manufactured by JIETENG. It is used for a variety of electronic components, including integrated circuits, resistors, capacitors, and transistors.

- Q: What is the origin of JIETENG's PCB circuit board?

- A: The PCB circuit board is manufactured by JIETENG in China.

- Q: What types of components can be used with PCB SMT Assembly?

- A: PCB SMT Assembly can be used for a variety of electronic components, including integrated circuits, resistors, capacitors, and transistors.

- Q: What are the benefits of using PCB SMT Assembly?

- A: PCB SMT Assembly is a cost-effective way to create complex circuits with a high level of accuracy and reliability. It also allows for a more compact design and faster assembly time.

- Q: What are the requirements for using PCB SMT Assembly?

- A: The components used for PCB SMT Assembly must be compatible with the printed circuit board, and the surface must be clean and free of any impurities or contaminants.