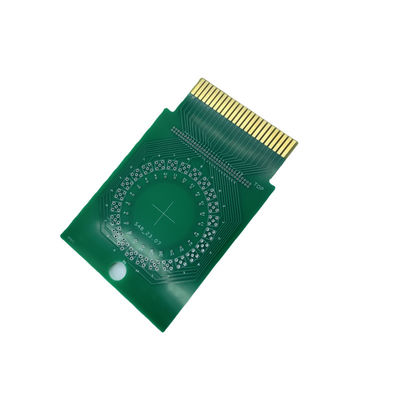

X Ray Testing Fr4 Pcb Board Assembly 0.2mm-3.2mm Board Thickness

| Place of Origin | China |

|---|---|

| Brand Name | JIETENG |

| Certification | ISO/TS16949/RoHS/TS16949 |

| Model Number | PCB circuit board |

| Minimum Order Quantity | Negotiable |

| Price | Negotiable |

| Packaging Details | Blank carton, vacuum packed |

| Delivery Time | 5-8 working day |

| Payment Terms | Negotiable |

| Supply Ability | 360000 square meters / year |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Board Thickness | 0.2mm-3.2mm | Material | FR4, Aluminum, Rogers, Etc. |

|---|---|---|---|

| Solder Mask Color | Green, White, Black, Etc. | Product Name | PCB Board Assembly |

| Min. Hole Size | 0.2mm | Min. Annular Ring | 3mil |

| Warranty | 1 Year | Assembly Type | SMT, Through Hole, Mixed, Etc. |

| Highlight | fr4 pcb board assembly,x ray testing pcb board assembly,fr4 pcb printed circuit board assembly |

||

Product Description:

Features:

- Product Name: PCB Board Assembly

- Copper Thickness: 1/2oz-4oz

- Material: FR4, Aluminum, Rogers, Etc.

- Min. Hole Size: 0.2mm

- Solder Mask Color: Green, White, Black, Etc.

- PCB Manufacturing: High Quality Printed Circuit Board Fabrication

- Circuit Board Assembly Process: Through Hole & Surface Mount Assembly

- Printed Circuit Board Manufacturing: High Quality Finished PCB Assembly

Technical Parameters:

| Property | Description |

|---|---|

| Testing | AOI, X-Ray, Flying Probe, Etc. |

| Surface Finish | HASL, ENIG, OSP, Etc. |

| Min. Hole Size | 0.2mm |

| Warranty | 1 Year |

| Solder Mask Color | Green, White, Black, Etc. |

| Min. Annular Ring | 3mil |

| Assembly Type | SMT, Through Hole, Mixed, Etc. |

| Min. Line Width/Space | 3mil/3mil |

| Board Thickness | 0.2mm-3.2mm |

| Product Name | PCB Board Assembly |

| Printed Circuit Board Manufacturing | Providing PCB fabrication services for single-sided, double-sided, and multi-layer PCB boards. |

| Circuit Board Assembly | Providing comprehensive PCB assembly services with various components including SMT, BGA, and through-hole. |

| Circuit Board Assembly Services | Offering full turnkey PCB assembly services including design, fabrication, assembly, and testing. |

Applications:

JIETENG – PCB Board Assembly – Reliable Quality and Durable Performance

JIETENG is a trusted manufacturer and supplier of PCB Board Assembly with a proven track record of providing reliable quality products that are tailored for various applications. Our PCB Board Assembly is designed with a focus on durability and performance, making it perfect for a wide range of applications including industrial, medical, and consumer electronics. Our PCB Board Assembly is manufactured with the highest quality FR4, aluminum, and Rogers materials in order to ensure its durability and long-lasting performance. Additionally, we offer a 1-year warranty with each of our PCB Board Assembly to ensure our customers’ satisfaction.

Our PCB Board Assembly is available in a wide range of thicknesses including 0.2mm-3.2mm, and our advanced manufacturing process allows us to achieve a minimum annular ring of 3 mil. Moreover, we offer various silk-screen colors such as white, black, and yellow to meet the needs of our customers. With our extensive experience in PCB Manufacturing and PCB Manufacturing Process, our highly skilled engineering team is able to provide our customers with the best possible solutions.

JIETENG is committed to providing reliable and high-quality products and services. Our in-depth knowledge of PCB Assembly and SMT Assembly allows us to develop custom solutions that meet the unique requirements of our customers. If you are looking for reliable PCB Board Assembly, look no further than JIETENG.

Customization:

JIETENG offers printed circuit board (PCB) assembly services for all types of circuit boards. Our circuit board assembly services include PCB manufacturing, soldering, and testing. We specialize in advanced circuit board assembly, including surface mount technology (SMT) and through hole technology (THT), with copper thickness from 1/2oz to 4oz, and min line width/space from 3mil/3mil. We use high-quality materials for our boards, with board thickness from 0.2mm to 3.2mm. All of our PCB board assembly services come with a 1-year warranty, and we test each board with AOI, X-Ray, and Flying Probe to guarantee quality.

Support and Services:

We provide full technical support and service for PCB Board Assembly. Our experienced staff can answer any of your questions regarding PCB Board Assembly, from design to fabrication to assembly.

Our services include:

- Design and fabrication assistance

- On-site troubleshooting and repair

- Testing and calibration of components

- Component supply and sourcing

- Assembly and testing services

If you have any questions regarding PCB Board Assembly, please don't hesitate to contact us.

Packing and Shipping:

Packaging and Shipping for PCB Board Assembly is a critical part of the production process. The following are the recommended procedures for packaging and shipping PCB Board Assembly.

- Pack each PCB Board Assembly in a static-safe bag.

- Ensure all components are secured with appropriate packaging materials (e.g. foam, bubble wrap, etc.).

- Place the PCB Board Assembly in a sturdy box and seal it securely.

- Label the box with the destination address and contact information.

- Ship the box via a reliable shipping carrier.

FAQ:

Q1: What is PCB Board Assembly?

A1: PCB Board Assembly is a production process for assembling components onto a printed circuit board (PCB) and soldering them in place to create a functioning finished product. The PCB Board Assembly is made by JIETENG and its model number is PCB circuit board, and it is originated from China.

Q2: What is included in PCB Board Assembly?

A2: PCB Board Assembly includes components such as resistors, capacitors, integrated circuits, and other electronic components that are soldered onto the board and connected to make the board function properly.

Q3: What is the process of PCB Board Assembly?

A3: The PCB Board Assembly process includes steps such as component placement, soldering, inspection, and testing. During this process, components such as resistors, capacitors, and integrated circuits are placed onto the board and soldered in place before they are tested to ensure that they are functioning properly.

Q4: Does PCB Board Assembly require any special equipment?

A4: Yes, special equipment such as a soldering iron, microscope, and other tools are required for the PCB Board Assembly process. Additionally, a clean environment with proper ventilation is necessary to ensure the quality of the assembly.

Q5: What type of PCB Board Assembly does JIETENG offer?

A5: JIETENG offers a wide range of PCB Board Assembly services, including through-hole and surface mount technology. The company also offers quick turnaround times and high quality of workmanship, making it an ideal choice for PCB Board Assembly needs.