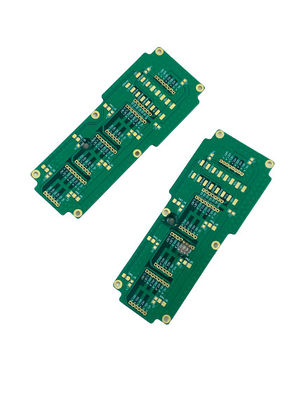

1oz Multi Layer Circuit Board With 0.1mm Min Line Spacing

| Place of Origin | China |

|---|---|

| Brand Name | JIETENG |

| Certification | ISO/TS16949/RoHS/TS16949 |

| Model Number | PCB circuit board |

| Minimum Order Quantity | Negotiable |

| Price | Negotiable |

| Packaging Details | Inner vacuum packing, outer standard carton |

| Delivery Time | 5-8 days for delivery |

| Payment Terms | Negotiable |

| Supply Ability | 150000 Square Meter/Square Meters per Year |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Board Thickness | 1.6mm | Assembly Service | Yes |

|---|---|---|---|

| Min Line Spacing | 0.1mm | Copper Thickness | 1oz |

| Silkscreen Color | White | Min Hole Size | 0.2mm |

| Min Line Width | 0.1mm | Surface Finish | HASL |

| Highlight | HASL Multilayer SMT PCB Board,1oz Multi Layer Circuit Board,SMT PCB Multi Layer Circuit Board |

||

Product Description:

SMT PCB Board is an integrated circuit board (IC board) designed for the electronic circuit board industry. It is a high-precision, high-quality product manufactured with stringent standards. With a minimum hole size of 0.2mm, a surface finish of HASL, a minimum line spacing of 0.1mm, a board thickness of 1.6mm and a copper thickness of 1oz, this board is designed for the most demanding of applications. It is capable of handling complex circuitry and integrated circuit board manufacturing, making it the perfect choice for any project requiring a reliable and durable integrated circuit board.

Features:

- Product Name: SMT PCB Board

- Electronic Circuit Board: Yes

- Printed Circuit Board: Yes

- Multi-Layer Circuit Board: Yes

- Min Line Width: 0.1mm

- Board Thickness: 1.6mm

- Surface Finish: HASL

- Silkscreen Color: White

- Layer: 2

Technical Parameters:

| Parameter | Value |

|---|---|

| Layer | 2 |

| Copper Thickness | 1oz |

| Min Hole Size | 0.2mm |

| Min Line Width | 0.1mm |

| Min Line Spacing | 0.1mm |

| Solder Mask Color | Green |

| Impedance Control | Yes |

| Assembly Service | Yes |

| Material | FR4 |

| Board Thickness | 1.6mm |

Applications:

JIETENG’s PCB circuit board is a reliable multi-layer electronic circuit board that is suitable for various applications and scenarios. It has a precise impedance control, a HASL surface finish, and a minimum line width of 0.1mm. The board thickness is 1.6mm, and the silkscreen color of the board is white. This printed circuit board is widely used in production and assembly of electronic devices, telecommunication, industrial automation, and medical equipment.

JIETENG’s PCB circuit board has excellent performance and outstanding quality. It has excellent temperature characteristics and high insulation performance, which makes it suitable for a wide range of applications. The board is also highly resistant to oxidation and corrosion, and it has good electrical performance even in harsh environments. In addition, this multi-layer circuit board has a high wiring density, and it is resistant to high-speed signals and high-frequency noise. This makes it suitable for applications such as signal transmission and high-speed data processing.

JIETENG’s PCB circuit board is an ideal choice for electronic device manufacturing, telecommunication, industrial automation, and medical equipment. It meets the highest requirements of the industry and provides reliable performance and excellent quality. With its precise impedance control, HASL surface finish, and minimum line width, this multi-layer circuit board can provide reliable performance in various applications and scenarios.

Customization:

Customized SMT PCB Board from JIETENG

JIETENG is a professional Printed Circuit Board (PCB) manufacturer in China. We provide customized PCB boards with high quality and competitive price.

Our SMT PCB board is made with the following features:

- Brand Name: JIETENG

- Model Number: PCB circuit board

- Place of Origin: China

- Material: FR4

- Board Thickness: 1.6mm

- Surface Finish: HASL

- Min Hole Size: 0.2mm

- Layer: 2

Our SMT PCB board is perfect for Multi-Layer Circuit Board and Electronic Circuit Board applications.

Support and Services:

At ABC Electronics, we are committed to providing quality technical support and services for SMT PCB board products. Our experienced and knowledgeable staff are available to assist you with any technical queries related to the design, installation, or maintenance of SMT PCB boards.

We provide a range of services to ensure that your SMT PCB boards are working correctly and in peak condition. These services include:

- Design and installation assistance

- Maintenance and troubleshooting

- Software and firmware updates

- Hardware upgrades and modifications

For more information on our SMT PCB board technical support and services, please contact us today.

Packing and Shipping:

SMT PCB Board Packaging and Shipping:

The SMT PCB Board should be carefully packed with an anti-static plastic bag, and then placed in a foam box lined with an ESD bag. The outer box should be marked with ESD protection signs. The board should be shipped in a well-protected carton.

FAQ:

Q1: What is SMT PCB board?

A1: SMT PCB board stands for surface mount technology printed circuit board, which is made by JIETENG with model number PCB circuit board and is produced in China.

Q2: What are the advantages of SMT PCB board?

A2: The main advantages of SMT PCB board include greater miniaturization with fewer components, higher component density, increased packaging reliability, and improved production throughput.

Q3: How is SMT PCB board made?

A3: SMT PCB board is made through a process of depositing a solder paste on the pads of the board, placing surface-mount components on the board, and then heating the board to reflow the solder.

Q4: What materials are used to make SMT PCB board?

A4: The materials used to make SMT PCB board typically include copper, glass fiber, resin, and solder mask.

Q5: What is the quality assurance for SMT PCB board?

A5: JIETENG has a strict quality assurance policy for SMT PCB board. All boards are tested using advanced inspection and testing equipment to ensure that they meet the highest quality standards.