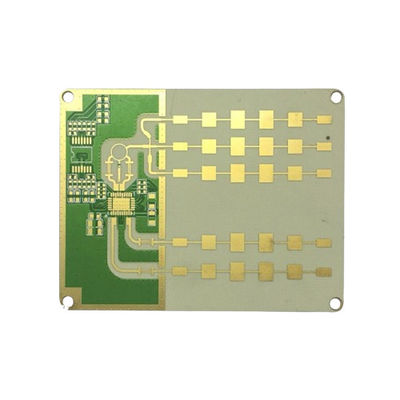

Precision Rogers PCB Board Assembly 3mil Min Line 0.2mm-3.2mm

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Board Thickness | 0.2mm-3.2mm | Product Name | PCB Board Assembly |

|---|---|---|---|

| Min. Hole Size | 0.2mm | Min. Line Width/Space | 3mil/3mil |

| Solder Mask Color | Green, White, Black, Etc. | Assembly Type | SMT, Through Hole, Mixed, Etc. |

| Min. Annular Ring | 3mil | Surface Finish | HASL, ENIG, OSP, Etc. |

| High Light | 3mil PCB Board Assembly,3.2mm PCB Board Assembly |

||

Product Description:

The PCB Board Assembly product is a sophisticated and meticulously crafted piece of technology that forms the backbone of countless electronic devices in the contemporary world. This product is the culmination of a highly detailed PCBA Manufacturing Process, which involves the integration of various electronic components onto a printed circuit board (PCB) to create a functional circuit board assembly. The PCB Board Assembly process is central to the production of a wide array of electronic devices, ranging from simple gadgets to complex computing systems.

Our PCB Board Assembly product is engineered with precision and is capable of accommodating various assembly types, including Surface Mount Technology (SMT), Through Hole (THT), and Mixed technology assemblies. Each of these assembly types is suitable for different applications and is selected based on the requirements of the electronic device in question. SMT is favored for its ability to accommodate a large number of small components and is known for its high speed and precision. Through Hole technology is chosen for its strong connections, which are ideal for components that will undergo mechanical stress. Mixed technology PCBAs leverage the benefits of both SMT and THT, catering to complex circuit board assembly needs.

A critical attribute of our PCB Board Assembly product is the testing process it undergoes to ensure the highest levels of quality and functionality. We employ various testing methods such as Automated Optical Inspection (AOI), X-Ray inspection, and Flying Probe tests. AOI is a crucial test that scans the PCB for soldering defects, missing components, and quality issues using high-speed cameras and advanced software algorithms. X-Ray inspection is utilized for detecting hidden problems like soldering short circuits or issues with the layers inside the PCB. The Flying Probe test, on the other hand, is instrumental for prototype boards where it methodically tests each component on the PCB without the need for a dedicated test fixture.

When it comes to the manufacturing precision of our PCB Board Assembly, we take great pride in our capabilities. We maintain a minimum annular ring size of 3mil (0.0762mm), which is essential for the stability of plated through holes and vias on the circuit board. This precise measurement ensures that there is enough copper around the holes to maintain the integrity of the electrical connections, even after repeated thermal cycling.

Moreover, the minimum hole size in our PCB Board Assembly product is 0.2mm, which allows for the placement of fine-pitch components, thereby enabling high-density PCB designs. This attribute is particularly important as it provides our clients with the flexibility to design complex and miniaturized electronic circuits while maintaining the robustness and reliability of the PCB.

The copper thickness in our PCB Board Assembly ranges from 1/2oz to 4oz. This range is carefully selected to accommodate different current-carrying requirements and to provide the necessary thermal management for the circuit board. A thicker copper layer can carry more current and is better at dissipating heat, which is crucial for high-power applications or devices that generate a significant amount of heat.

In conclusion, our PCB Board Assembly product embodies the pinnacle of the Circuit Board Assembly Process. It is defined by its versatility in assembly types, the thoroughness of its testing procedures, and the precision of its manufacturing specifications. With a focus on quality, reliability, and technological advancement, our PCB Board Assembly service is designed to meet the demanding needs of modern electronics, ensuring that our clients receive a product that not only meets but exceeds their expectations. Whether for prototypes or full-scale production runs, our PCB Board Assembly is the solution for your electronic manufacturing requirements.

Features:

- Product Name: PCB Board Assembly

- Assembly Type: SMT (Surface Mount Technology), Through Hole, Mixed, Etc.

- Silk Screen Color: White, Black, Yellow, Etc.

- Solder Mask Color: Green, White, Black, Etc.

- Testing Procedures: Automated Optical Inspection (AOI), X-Ray Inspection, Flying Probe Testing, Etc.

- Warranty: 1 Year

- High-Quality Circuit Board Assembly

- Advanced PCBA Manufacturing Process

- Precision Printed Circuit Board Manufacturing

Technical Parameters:

| Attribute | Details |

|---|---|

| Warranty | 1 Year |

| Solder Mask Color | Green, White, Black, Etc. |

| Copper Thickness | 1/2oz-4oz |

| Min. Hole Size | 0.2mm |

| Material | FR4, Aluminum, Rogers, Etc. |

| Product Name | PCB Board Assembly |

| Assembly Type | SMT, Through Hole, Mixed, Etc. |

| Min. Line Width/Space | 3mil/3mil |

| Board Thickness | 0.2mm-3.2mm |

| Testing | AOI, X-Ray, Flying Probe, Etc. |

Applications:

The JIETENG PCB circuit board, with its Model Number PCB circuit board, is a high-precision product originating from China, designed to cater to a variety of application occasions and scenarios in the realm of PCB Manufacturing. Its features, such as a minimum line width/space of 3mil/3mil and a minimum hole size of 0.2mm, make it an ideal candidate for intricate circuit board assembly processes that require meticulous attention to detail.

The board thickness of the JIETENG PCB circuit board can range from 0.2mm to 3.2mm, accommodating a wide spectrum of design specifications and ensuring adaptability across various industries. The silk screen color options, including White, Black, Yellow, etc., provide a customizable aspect to the circuit boards, allowing for distinct visual identification that can be important in complex electronics.

Constructed with materials such as FR4, Aluminum, and Rogers, the JIETENG model ensures reliability and performance. These materials are chosen for their proven properties, such as high-temperature resistance and excellent electrical insulation, which are critical for ensuring the longevity and functionality of the PCBs during and after the circuit board assembly process.

The JIETENG PCB circuit board is indispensable in sectors such as telecommunications, where precision and durability are non-negotiable. It is also extensively used in medical devices, automotive electronics, and aerospace technology, where the circuit board assembly must meet stringent standards and withstand challenging environments. The versatility of the JIETENG PCB circuit board also extends to consumer electronics, where innovative technology meets mass production, requiring a seamless circuit board assembly process to maintain high-quality control.

Furthermore, in the realm of industrial control systems, the JIETENG PCB circuit board is key to managing complex processes. The precision in the PCB Manufacturing of the JIETENG model ensures that every printed circuit board functions as intended, which is vital for the safety and efficiency of industrial applications. The robust nature of the JIETENG PCB circuit board, paired with its ability to be customized according to specific needs, makes it a preferred choice for engineers and designers across various high-tech fields.

Customization:

Brand Name: JIETENG

Model Number: PCB circuit board

Place of Origin: China

Silk Screen Color: Available in a variety of colors including White, Black, Yellow, etc., to meet your Printed Circuit Board Manufacturing design requirements.

Copper Thickness: Ranging from 1/2oz to 4oz to accommodate different applications and enhance the reliability of your Circuit Board Assembly.

Surface Finish: Options include HASL, ENIG, OSP, etc., ensuring a high-quality finish for your Printed Circuit Board Manufacturing needs.

Board Thickness: From 0.2mm to 3.2mm, we provide the flexibility to support diverse product specifications.

Testing: Comprehensive testing services including AOI (Automated Optical Inspection), X-Ray inspection, and Flying Probe to guarantee the performance of your JIETENG PCB circuit boards.

Support and Services:

Our Product Technical Support team is dedicated to providing exceptional service and support for our PCB Board Assembly products. We offer a comprehensive range of services to ensure your PCB assembly needs are met with precision and efficiency. Our support includes troubleshooting assistance, product-specific documentation, firmware updates, and best practices for maintenance and handling.

For technical inquiries or issues, our team is readily available to offer guidance and solutions to optimize the performance of your PCB Board Assembly. We strive to respond promptly and effectively to all support requests to minimize any potential downtime or disruptions to your operations.

In addition to reactive support, we also provide proactive services such as ongoing monitoring, performance analysis, and recommendations for system improvements. Our goal is to help you maintain the highest level of functionality and reliability throughout the lifecycle of your PCB Board Assembly product.

Please note that while we aim to resolve most issues remotely, some situations may require hands-on technical service. In such cases, we will coordinate with you to arrange for the appropriate service interventions to address and resolve the issue at hand.

We are committed to continuous improvement and customer satisfaction. Our technical support team is constantly updating their knowledge and skills to stay at the forefront of PCB technology and to provide you with the best possible service. We encourage our customers to provide feedback on our products and services so that we can continue to serve you better.

Packing and Shipping:

Each PCB Board Assembly is meticulously packaged to ensure its safe arrival. The boards are first statically shielded, then wrapped in bubble wrap for cushioning. Next, they are securely placed in a rigid cardboard box with foam inserts that conform to the shape of the assembly, preventing any movement during transport. The outer box is sealed with tamper-evident tape and clearly labeled with handling instructions. We use reliable courier services for shipping, providing you with a tracking number to monitor the delivery status of your order. Please inspect the package upon arrival and report any damage immediately for prompt resolution.

FAQ:

Q1: What is the brand name of the PCB circuit board?

A1: The brand name of the PCB circuit board is JIETENG.

Q2: Can you provide the model number for the PCB circuit board?

A2: Yes, the model number for our PCB circuit board is "PCB circuit board."

Q3: Where is the JIETENG PCB circuit board manufactured?

A3: The JIETENG PCB circuit board is manufactured in China.

Q4: Is the JIETENG PCB circuit board suitable for high-frequency applications?

A4: Yes, the JIETENG PCB circuit board is designed to meet the demands of high-frequency applications, ensuring reliable performance and signal integrity.

Q5: Can I order custom specifications for the JIETENG PCB circuit board?

A5: Absolutely, we offer customization options for the JIETENG PCB circuit board to meet your specific requirements. Please provide your specifications when placing an order.