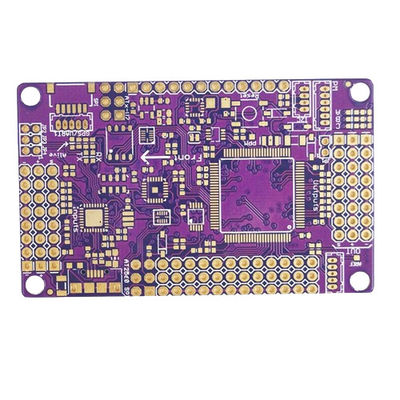

Customized PCB circuit board 6-layer board purple ink inside and outside 2OZ copper thickness

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Components | Passive And Active Components | Board Size | Up To 500mm X 500mm |

|---|---|---|---|

| Components Height | 0.2mm-25.0mm | Board Thickness | 0.4mm-4.0mm |

| Components Size | 01005-5050 | Surface Finish | HASL, ENIG, OSP, Immersion Gold, Etc. |

| Components Placement | ±0.02mm | Component Pitch | 0.2mm-5.0mm |

| High Light | purple ink Customized PCB circuit board,6-layer Customized PCB circuit board,2OZ Customized PCB circuit board |

||

Product Description:

The SMT Assembly Service we offer stands at the forefront of the electronics manufacturing industry, providing an unparalleled commitment to quality and precision. With a standard lead time of just 7-10 days, our service is not only efficient but also reliable, ensuring that your projects are completed within the necessary timeframe without compromising on workmanship. Our service is designed to cater to a wide range of component sizes, from the tiny 01005 to the larger 5050, providing versatility for various application requirements.

Our state-of-the-art SMT Assembly Service boasts an impressive component placement precision of ±0.02mm. This exceptional level of accuracy ensures that each component is placed with the utmost precision, which is crucial for the functionality and reliability of the final product. Whether it's for consumer electronics, medical devices, or aerospace applications, the precision we offer is pivotal in the increasingly miniaturized world of electronic components.

When it comes to component height, our service can handle components ranging from a minimal height of 0.2mm to a substantial height of 25.0mm. This broad range guarantees that our SMT Assembly Service is suitable for virtually any type of surface-mounted device, providing the flexibility needed to meet the demands of complex and diverse electronic assemblies. This capability ensures that we can accommodate high-profile components, such as connectors and transformers, as easily as we can the smaller, low-profile resistors and capacitors.

The SMT Assembly Service we provide is also equipped to handle board thicknesses varying from 0.4mm to 4.0mm. This specification allows for the assembly of both thin, flexible circuits and thick, rigid boards, ensuring compatibility with a multitude of electronic product designs. The ability to work with such a range of board thicknesses underscores the adaptability of our service, making it a one-stop solution for any SMT assembly needs.

Our SMT Assembly Maintenance Service is an integral part of our offering. We understand that the maintenance of SMT assembly lines is critical for the long-term performance and reliability of electronic products. As a result, we provide comprehensive maintenance services that ensure your SMT assembly operations run smoothly and efficiently. Our technicians are highly skilled and trained to identify potential issues before they become problems, minimizing downtime and maintaining productivity.

In addition to the precision and flexibility of our SMT Assembly Service, we also offer Surface Mount Maintenance Services. This service is designed to assist with the upkeep of surface mount technology equipment, ensuring that your SMT line remains in peak condition. Regular maintenance is vital for avoiding costly repairs and production delays, and our team of experts is equipped to provide the highest level of service to keep your assembly line operational.

Our Surface Mount Maintenance Service is not just about prevention; it's also about optimization. We work closely with our clients to improve their SMT processes, increase their throughput, and reduce waste. By staying at the cutting edge of SMT technology and best practices, we can provide insights and recommendations that will give your operations a competitive edge. Every aspect of our service is designed to provide you with peace of mind, knowing that your SMT assembly is in the hands of professionals.

In summary, our SMT Assembly Service is a comprehensive solution that covers all aspects of surface mount technology assembly. From accommodating a wide range of component sizes and heights to handling various board thicknesses with extreme precision, our service is designed to meet the needs of any electronic product manufacturer. With our accompanying maintenance services, we ensure not only the high-quality assembly of your electronic components but also the ongoing reliability and efficiency of your SMT production line.

Features:

- Product Name: SMT Assembly Service

- Surface Finish: HASL, ENIG, OSP, Immersion Gold, Etc.

- Components Orientation: ±0.02mm

- Components Height: 0.2mm-25.0mm

- Components Placement: ±0.02mm

- Lead Time: 7-10 Days

Technical Parameters:

| Attribute | Details |

|---|---|

| Board Size | Up To 500mm X 500mm |

| Manufacturing Process | Surface Mount Technology (SMT) |

| Components | Passive And Active Components |

| Board Thickness | 0.4mm-4.0mm |

| Lead Time | 7-10 Days |

| Testing | Flying Probe Test, X-Ray Inspection, AOI, Etc. |

| Components Size | 01005-5050 |

| Surface Finish | HASL, ENIG, OSP, Immersion Gold, Etc. |

| Components Type | BGA, QFN, SOP, PLCC, SOIC, Etc. |

| Component Pitch | 0.2mm-5.0mm |

Applications:

JIETENG, recognized for its superior SMT Assembly Services, offers its state-of-the-art PCB circuit board model, meticulously crafted to meet diverse industry needs. Originating from China, the JIETENG brand has become synonymous with precision and reliability in the electronic manufacturing sector. The company takes pride in its ability to place components with an exceptional accuracy of ±0.02mm, ensuring that every assembled board meets the highest standards of quality and performance.

With a commendable lead time of 7-10 days, JIETENG is well-equipped to handle urgent and high-volume demands without compromising on the quality of the SMT Assembly Maintenance Service. The service is capable of accommodating a wide range of components, from passive to active, making it a versatile solution for various applications. The component pitch capability ranges from a fine 0.2mm to 5.0mm, thereby catering to intricate designs and complex circuitries.

The SMT Assembly Facility Service offered by JIETENG is perfect for handling board sizes up to 500mm x 500mm, thus providing ample space for large-scale and multi-functional PCBs used in industries such as telecommunications, computing, medical devices, and automotive electronics. Whether it's a prototype or a full production run, JIETENG's Surface Mount Assembly Facility Service ensures that each board is assembled with meticulous care and precision.

Application occasions for the JIETENG SMT Assembly Service include the manufacturing of consumer electronics, where the demand for compact and efficient PCBs is ever-growing. In the aerospace and defense industry, the need for reliable and ruggedized circuit boards makes JIETENG an ideal partner. The medical industry also benefits from this service, as precision and reliability are paramount for medical devices. JIETENG's commitment to quality makes it a preferred choice for critical applications where failure is not an option.

Scenarios where the JIETENG SMT Assembly Service excels include the rapid prototyping of new products, where time-to-market is critical. The service is also invaluable for the mass production of electronic goods, where consistency and throughput are key to meeting market demands. Additionally, the service is adept at handling the complexities of modern IoT devices, which require sophisticated and miniaturized PCBs. For companies looking to upgrade or maintain their electronic components, JIETENG also provides an exemplary SMT Assembly Maintenance Service.

In summary, JIETENG's SMT Assembly Services are well-suited for a multitude of scenarios, ranging from the production of high-tech gadgets to the maintenance of complex industrial equipment. The company's commitment to delivering high-quality assembly solutions makes it a top choice for businesses seeking a reliable and efficient SMT Assembly Facility Service.

Customization:

Brand Name: JIETENG

Model Number: PCB circuit board

Place of Origin: China

Components Orientation Precision: ±0.02mm

Components Type: BGA, QFN, SOP, PLCC, SOIC, Etc.

Components Placement Precision: ±0.02mm

Components: Passive And Active Components

Lead Time: 7-10 Days

With JIETENG's Surface Mount Technology Assembly Service , you receive precision and reliability for your PCB circuit board needs. Our SMT Assembly Service, based in China, offers impeccable components orientation and placement with an accuracy of ±0.02mm. Catering to a variety of components types including BGA, QFN, SOP, PLCC, and SOIC among others, we are equipped to handle both passive and active components. Rely on our SMT Assembly Maintenance Service for consistent quality and a fast lead time of just 7-10 days, ensuring your projects stay on track.

Support and Services:

The SMT (Surface Mount Technology) Assembly Service offers comprehensive technical support and services designed to ensure the successful implementation and operation of your SMT assembly needs. Our team of experienced technicians and engineers is dedicated to providing expert assistance in all aspects of the SMT assembly process. We offer a range of services, including but not limited to:

- Design for Manufacturability (DFM) analysis to ensure your PCB designs are optimized for the SMT assembly process, reducing potential issues and improving overall efficiency.

- Process optimization to help refine your assembly process, enhance production throughput, and minimize defects.

- Solder paste inspection and quality control measures to ensure the integrity and reliability of your solder joints.

- Advanced troubleshooting for any SMT-related issues that may arise during the production process, including component placement errors, soldering defects, and more.

- On-demand technical guidance for setup, operation, and maintenance of your SMT assembly line equipment.

- Training services to educate your staff on best practices, machine operation, and maintenance procedures to maximize the performance and lifespan of your SMT equipment.

- Firmware and software updates for your SMT equipment, ensuring you have access to the latest features and improvements.

Please note that while we strive to provide extensive support, our services do not include on-site repairs or maintenance, which should be addressed by your equipment manufacturer or a qualified service provider. For any additional questions or to access our technical support, please refer to our contact page for the appropriate channels to reach out to our service team.

Packing and Shipping:

Our SMT (Surface Mount Technology) Assembly Service ensures that your products are packaged with the utmost care. Each assembled PCB (Printed Circuit Board) is inspected for quality assurance before being securely packed in anti-static bags. These bags are then cushioned with protective foam inserts and placed into sturdy, custom-sized boxes to prevent any movement during transit.

For shipping, we partner with reliable courier services that specialize in the safe transportation of electronic components. You will receive a tracking number once your package is dispatched, allowing you to monitor its journey to your specified destination. We take every precaution to ensure that your SMT Assembly order arrives on time and in perfect working condition.

FAQ:

Q1: What types of PCB circuit boards can JIETENG manufacture?

A1: JIETENG specializes in the manufacture of a wide range of PCB circuit boards, including single-sided, double-sided, and multi-layer PCBs. We can accommodate various complexities and design requirements to meet your specific needs.

Q2: Can JIETENG provide design services for PCB circuit boards?

A2: Yes, JIETENG has a team of experienced engineers who can assist you with your PCB design needs. We can help optimize your designs for manufacturing efficiency and cost-effectiveness while ensuring the quality and performance of your PCB circuit boards.

Q3: What is the lead time for a PCB circuit board order from JIETENG?

A3: The lead time for a PCB circuit board order varies depending on the complexity of the design and the quantity required. However, we are committed to providing quick turnaround times and will work closely with you to meet your deadlines. Please contact us with your specific requirements for a more accurate estimate.

Q4: Are JIETENG's PCB circuit boards compliant with international quality standards?

A4: Absolutely. JIETENG's PCB circuit boards are manufactured in compliance with international quality standards. We ensure that all products are rigorously tested and inspected before shipment to guarantee the highest level of quality and reliability.

Q5: Does JIETENG offer prototype services for PCB circuit boards?

A5: Yes, JIETENG offers prototype services to help you validate your PCB designs before moving to mass production. This service allows you to test and refine your circuit boards to ensure they meet your functional requirements.