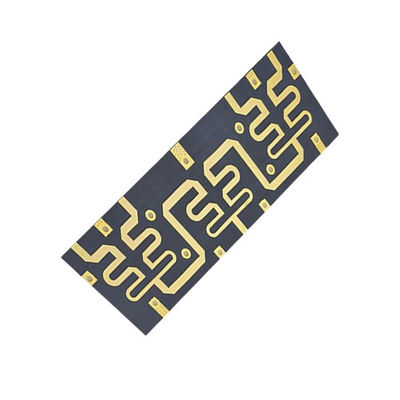

PTFE sheet multi-layer PCB manufacturing 0.2-3.2mm HASL ENIG OSP surface treatment

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Surface Finish | HASL, ENIG, OSP, Immersion Silver, Immersion Tin, Etc. | Material | FR4, High TG FR4, Halogen Free, Rogers, Etc. |

|---|---|---|---|

| Board Thickness | 0.2-3.2mm | Copper Thickness | 1-4oz |

| Impedance Control | Yes | Min. Hole Size | 0.2mm |

| Min. Line Width | 0.1mm | Solder Mask Color | Green, Blue, White, Black, Red, Etc. |

| High Light | PTFE sheet multi-layer PCB,HASL multi-layer PCB,ENIG multi-layer PCB |

||

Product Description:

The advent of increasingly complex electronic devices has necessitated the development of more sophisticated circuit board technologies. Among these, the Multi-Layer Printed Circuit Board (PCB) stands out as a critical component in modern electronics. Our Multilayer PCB Fabrication product is at the forefront of Multi-Layer Printed Circuit Board Production, tailored to meet the exacting standards of contemporary electronic devices that require high-density interconnection and reliability.

Built with precision, our Multilayer PCBs offer unparalleled performance, thanks to stringent Impedance Control. This feature ensures that the electrical characteristics of the circuit boards match the requirements of high-speed signals, thereby reducing signal loss, crosstalk, and electromagnetic interference. The precise impedance control is a testament to our commitment to delivering products that cater to the delicate needs of advanced electronic assemblies.

In the realm of Multi-Level Printed Wiring Board Creation, one of the most demanding specifications is the minimization of the Line Width. Our fabrication process proudly achieves a Min. Line Width of 0.1mm, allowing for a higher density of circuits per unit area. This miniaturization is vital for modern electronics, which demand more functionality in increasingly smaller packages.

The aesthetics and functionality of a PCB are significantly enhanced by its Solder Mask Color, and our product offers a range of options including Green, Blue, White, Black, Red, among others. The choice of solder mask not only provides a distinct look to the PCB but also contributes to the protection of the copper circuits from environmental factors and reduces the likelihood of solder bridging between closely spaced solder pads.

Adaptability is key in Multi-Level Printed Wiring Board Creation, and our Multilayer PCB Fabrication service caters to various design complexities by offering a Layer Count ranging from 2 to 20 layers. This versatility ensures that whether our clients are working on a straightforward two-layer board or a complex twenty-layer design, our products can accommodate the intricacies and interlayer connections required for high-performance and multi-functional electronics.

Moreover, our commitment to precision is further evident in our achievement of a Min. Line Spacing of 0.1mm. This tight spacing capability is crucial for maintaining signal integrity and reducing the potential for short-circuits in densely packed layouts. Such attention to detail is what sets our Multi-Layer Printed Circuit Board Production apart, providing the assurance of reliability in the most demanding applications.

Every Multilayer PCB we fabricate undergoes rigorous testing and quality control measures to ensure it meets the highest standards. We understand that in the world of electronics, even the smallest imperfection can lead to significant consequences. Therefore, our quality assurance processes are designed to identify and eliminate any defects that could compromise the performance of the PCB.

In conclusion, our Multilayer PCB Fabrication product stands as a cornerstone in the field of Multi-Layer Printed Circuit Board Production. Combining advanced features such as Impedance Control, tight Line Width and Spacing specifications, a variety of Solder Mask Colors, and a broad range of Layer Counts, we deliver PCBs that are not only aesthetically pleasing but also electrically superior and highly reliable. Trust our expertise in Multi-Level Printed Wiring Board Creation to power the next generation of electronic innovations.

Features:

- Product Name: Multilayer PCB Fabrication

- Copper Thickness: 1-4oz

- Min. Hole Size: 0.2mm

- Solder Mask Color: Green, Blue, White, Black, Red, Etc.

- Material: FR4, High TG FR4, Halogen Free, Rogers, Etc.

- Min. Line Width: 0.1mm

- Multi-Level Printed Circuit Board Fabrication

- Multi-Level Printed Circuit Board Fabrication

- Multi-Level Printed Circuit Board Fabrication

Technical Parameters:

| Parameter | Specification |

|---|---|

| Solder Mask Color | Green, Blue, White, Black, Red, Etc. |

| Min. Line Spacing | 0.1mm |

| Min. Hole Size | 0.2mm |

| Copper Thickness | 1-4oz |

| Surface Finish | HASL, ENIG, OSP, Immersion Silver, Immersion Tin, Etc. |

| Layer Count | 2-20 |

| Min. Line Width | 0.1mm |

| Board Thickness | 0.2-3.2mm |

| Material | FR4, High TG FR4, Halogen Free, Rogers, Etc. |

| Silkscreen Color | White, Black, Yellow, Etc. |

Applications:

The JIETENG brand is renowned for its expertise in Multi-Layer PCB Manufacturing , delivering high-quality PCB circuit boards that cater to a wide range of applications. With a model number synonymous with precision and reliability, these PCB circuit boards are designed to meet intricate electronic needs. Manufactured in China, JIETENG PCBs are a testament to the country's technological advancements in the electronics sector.

JIETENG PCBs boast a minimum line spacing and width of 0.1mm, allowing for high-density component placement, which is crucial in modern electronic devices where space is at a premium. The board thickness ranges from 0.2mm to 3.2mm, providing versatility for different product requirements. Whether for slim consumer electronics or robust industrial systems, JIETENG's PCBs can be tailored to fit.

The materials used in these PCBs include standard FR4, High TG FR4 for enhanced thermal resistance, Halogen Free for eco-friendliness, and Rogers for high-frequency applications. This variety ensures that whether the focus is on durability, environmental standards, or performance, there is a suitable material option available.

With Impedance Control , JIETENG PCBs ensure signal integrity, which is especially vital in high-speed electronic circuits. This feature makes JIETENG PCBs ideal for use in complex electronic systems where consistent performance is non-negotiable.

The application occasions and scenarios for JIETENG's PCB products are vast. They are integral in the telecommunications sector, powering routers and switches that require reliable Multi-Layer PCB Manufacturing . In the realm of computing, from servers to personal computers, these PCBs are used for their capacity to support dense component layouts and manage heat effectively. The medical industry also benefits, utilizing JIETENG's precision PCBs in critical diagnostic and treatment equipment.

Automotive and aerospace industries rely on JIETENG's robust PCBs for navigation, control systems, and entertainment systems. The exacting standards of Multi-Layer PCB Component Assembly ensure that these complex applications can function reliably under demanding conditions. Consumer electronics like smartphones, tablets, and gaming consoles also employ these multi-layer PCBs for their compact designs and the need for efficient space utilization.

In summary, JIETENG's PCB circuit boards are an essential component for industries seeking high-quality, reliable Multi-Layer PCB Manufacturing and assembly. With its advanced features, material options, and meticulous manufacturing process, JIETENG stands as a pinnacle of PCB technology, ready to meet the diverse demands of modern electronics.

Customization:

Brand Name: JIETENG

Model Number: PCB circuit board

Place of Origin: China

Impedance Control: Yes

Board Thickness: 0.2-3.2mm

Silkscreen Color: White, Black, Yellow, Etc.

Material: FR4, High TG FR4, Halogen Free, Rogers, Etc.

Solder Mask Color: Green, Blue, White, Black, Red, Etc.

Explore the realms of Multi-Level Printed Wiring Board Creation with JIETENG, your trusted partner in bespoke Multi-Layer PCB Component Assembly . Each JIETENG PCB circuit board is meticulously crafted in China , offering precision Impedance Control and a versatile range of Board Thickness from 0.2-3.2mm. Choose from an array of Silkscreen Colors including White, Black, and Yellow, to match your design aesthetics. Our material selection, including FR4, High TG FR4, and Halogen Free options, caters to a variety of Multi-Layer PCB Component Assembly requirements. Top it all off with your choice of Solder Mask Color , selecting from Green, Blue, White, Black, Red, and more to customize your multi-layer circuit board to perfection.

Support and Services:

Our Multilayer PCB Fabrication product comes with comprehensive technical support and services to ensure your complete satisfaction with our product. Our support includes access to a team of experienced engineers who can assist with design, layout, and manufacturing challenges. We also offer a range of services to help optimize the performance and reliability of your PCBs.

Technical support for our Multilayer PCB Fabrication includes troubleshooting assistance, guidance on material selection, and advice on stack-up options to meet your specific requirements. Our experts are available to help resolve any issues that may arise during the design or production process, ensuring that your PCBs are fabricated to the highest standards.

In addition to technical support, our services include detailed documentation, design rule checks (DRC), and electrical testing to verify the integrity of the PCBs. We work closely with our clients to provide tailored solutions that align with their project timelines and budget constraints. Our goal is to deliver exceptional quality and service to support the success of your projects.

Please note that our technical support and services are intended to complement the knowledge and expertise of your own design and engineering teams. We encourage our clients to engage with us early in the design process for the best outcomes.

Packing and Shipping:

The Multilayer PCB Fabrication product is carefully packaged to ensure it reaches its destination in perfect condition. Each PCB is individually wrapped in anti-static material to prevent electrostatic discharge damage during transport. The wrapped PCBs are then placed into a rigid, custom-fit cardboard box with cushioning material on all sides to mitigate any impact during shipping. This box is sealed with heavy-duty packing tape and clearly labeled with handling instructions.

For shipping, the packaged PCBs are grouped into larger, durable shipping containers. These containers are designed to be stackable, providing stability and protection during transit. Each shipping container is also sealed and labeled appropriately with the product details, destination, and tracking information to ensure that it is handled correctly and arrives safely at its final destination.

FAQ:

Q1: What materials are used in the JIETENG PCB circuit board?

A1: The JIETENG PCB circuit board is made using high-quality laminates, copper foil, and other materials that meet industry standards for multilayer PCB fabrication. The specific materials used can vary depending on the application and customer requirements.

Q2: Can the JIETENG PCB circuit board support high-frequency applications?

A2: Yes, the JIETENG PCB circuit board is designed to support high-frequency applications. The fabrication process includes attention to detail in layer stack-up and material selection to ensure signal integrity in high-frequency environments.

Q3: What is the maximum number of layers available for the JIETENG PCB circuit boards?

A3: The maximum number of layers for the JIETENG PCB circuit board depends on the complexity of your design and application. Please contact us with your specific requirements, and we will provide you with the best solution to meet your needs.

Q4: How does the JIETENG ensure the quality of its PCB circuit boards?

A4: JIETENG ensures quality through rigorous testing and quality control procedures. This includes electrical testing, visual inspection, and other industry-standard practices to ensure that each PCB circuit board meets the high standards expected from a product manufactured in China.

Q5: What are the lead times for the JIETENG PCB circuit board manufacturing?

A5: Lead times for JIETENG PCB circuit board manufacturing can vary depending on the complexity of the board and current production capacity. Generally, we aim to have a quick turnaround time while ensuring quality. For specific lead times related to your project, please contact us with your details.